If you’re like most people, you probably only really heard about 3D printing a decade or two ago. It probably sounded like a futuristic concept that was being worked on in some top-secret lab.

3D printing has been around for a long time, though, with the theory itself originating in the 40s!

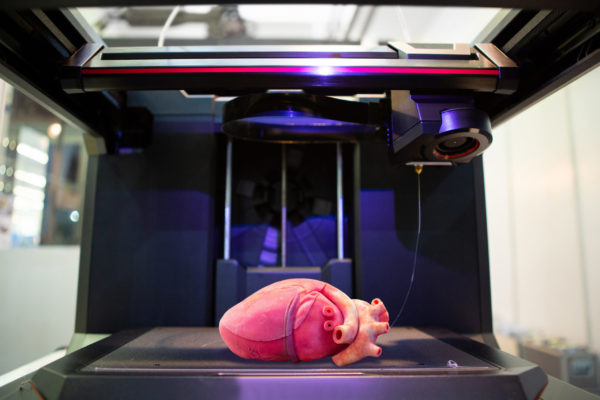

Since this innovative tech was first theorized, it’s evolved considerably, as it’s now used in everything from the sustainable construction of houses to the development of kidneys and prosthetic legs. Let’s take a look at a short, deconstructed history of it.

Science fiction come to life

3D printing first appeared as a concept in 1945 in a short story written by Murray Leinster, called “Things Pass By.” In this story, magnetronic plastics (used to make houses and ships back then) are fed to a moving arm that makes drawings in the air from drawings it scans with photo-cells. Then, the plastic comes out of the end of the drawing arm and hardens.

As we know, this concept has since passed on from the realms of sci-fi into reality.

The 1960s-1971: The foundational years of 3D printing

The Teletype Corporation invented inkjet technology in the 1960s. It allowed a drop of material to be pulled from a nozzle using electronics which resulted in the creation of a printer capable of printing 120 characters per second. This paved the way for consumer desktop printing.

By 1971, Teletype, along with Johannes F. Gottwald, was experimenting with primitive 3D printing by using melted wax to create a shape predetermined by the inkjet’s movement upon each layer. The device they used was dubbed the Liquid Metal Recorder and was evidence that printing could do much more than spill out ink.

The 1980s: The early years of 3D Printing and its first patent

The first documented instance of actual 3D printing goes back to the early 80s in Japan. In 1981, lawyer, Hideo Kodama, came up with a layer-by-layer approach for manufacturing by using photosensitive resin that had been polymerized by UV light.

He wanted to create a rapid prototyping mechanism, and even though he failed to patent the requirement for this technology, he is often credited as the inventor of this manufacturing system, which is seen as an early version of a modern stereolithography (SLA) machine.

A few years later, a trio of French researchers, Alain Le Méhauté, Olivier de Witte, and Jean-Claude André decided to use liquid monomers to create solids with the help of lasers. Just like Kodama, they were unable to patent their technology, but are still credited with coming up with the system.

Charles Hull, in the same year as the French scientists, filed the first patent for SLA. An American furniture builder, he was trying to overcome his frustration with not being able to easily create small, custom parts.

So, he developed a proprietary system for creating 3D models by curing photosensitive resin layer by layer.

After applying for his patent in 1986, he went on to found the 3D Systems Corporation, which released the first commercial SLA 3D printer – the SLA-1 in 1988.

The 90s and 2000s: The growth of 3D printing

By the 90s, a lot of companies had entered the 3D printing race, experimenting with the various technologies developed in the previous decade including SLA, Selective Laser Sintering (SLS), and Fused Deposition Modeling (FDM).

In 2006, the first commercially available SLS printer was released, a game-changer in terms of manufacturing on demand.

CAD tools also became more accessible during this time, allowing individuals to design and develop their own 3D models on their PCs.

3D printers remained expensive and difficult to use, but innovations kept filtering through to inch us closer to where we are today with it.

By 2005, Open Source changed the dynamic by increasing access to 3D printing technology for everyone. Dr. Adrian Bowyer created the RepRap Project through it, which created a 3D printer that could build another 3D printer as well as other 3D printed projects.

The first prosthetic leg was printed in 2008. In 2009, FDM patents filed in the 80s moved into the public domain, making them accessible to more companies, leading to greater competition and a decrease in prices.

3D printing today

The price of 3D printers has continued to decrease along with an increase in quality and ease of use, making them more accessible than ever to the public. There are a variety of new materials available and people are experimenting with materials like chocolate or pasta! The innovations that the printers are spurring are amazing, with the manufacturing of everything from prosthetic limbs to food to the world’s largest functional 3D printed building, completed in 2019!

Tell us what you think!

What excites you the most about 3D printing? What would you like to build with a 3D printer? Leave your thoughts in the comment section below and don’t forget to share this article with someone you know would love the information.